The DXGF60-60-15 Isobaric Filling Machine is a 3-in-1 system integrating rinsing, filling, and capping functionalities, specifically designed for glass bottles used in beer, carbonated beverages, juices, mineral water, and other liquid products. Developed with advanced international technology and optimized for glass bottle filling processes, this machine ensures efficient, stable, and hygienic production. Its compact design, reliability, and ease of maintenance make it an ideal solution for breweries and beverage manufacturers.

Glass Bottle Beer & Beverage Filling Machine

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

Key Highlights

-

Hygienic Design: SUS 316L stainless steel contact parts, CIP cleaning system.

-

Precision & Safety: Isobaric filling (±1ml accuracy), magnetic torque capping, anti-breakage buffer mechanisms.

-

Automation: Touchscreen HMI, PLC control, minimal manual intervention.

-

Adaptability: Adjustable for various glass bottle sizes without height reconfiguration.

Applications

-

Primary: Beer, carbonated beverages, juices, and mineral water in glass bottles.

-

Scale: Ideal for medium-to-large-scale production lines requiring efficiency and hygiene.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | DXGF60-60-15 |

| Bottle Type | Glass (beer & beverage-specific) |

| Bottle Height Range | 180-350mm |

| Bottle Diameter Range | φ60-φ120mm |

| Rinsing Valve Stations | 60 |

| Filling Valve Stations | 60 |

| Capping Head Stations | 15 |

| Working Air Pressure | 0.7MPa |

| Filling Temperature | ≤8°C (low-temperature for beer) |

| Production Capacity | 18,000 bottles/hour (500ml standard) |

| Power Supply | 15KW |

| Dimensions (L×W×H) | 7120×4650×2700mm |

| Machine Weight | 17,000KG |

Core Components

| Component | Brand |

|---|---|

| Main Motor + Reducer | ABB (Germany) |

| Inverter | Siemens (Germany) |

| PLC Control System | Siemens (Germany) |

| Touchscreen HMI | Siemens (Germany) |

| Low-Voltage Components | Schneider (France) |

| Photoelectric Sensors | Leuze (Germany) |

| Pneumatic Components | Festo (Germany) |

| Proportional Control Valve | SED (Germany) |

| Lubrication System | SKF-BEKA (Germany) |

Key Features

- Fully Automated Integration: Combines rinsing, filling, and capping in one seamless process, minimizing manual intervention and maximizing efficiency.

- Glass Bottle-Specific Handling: Utilizes flexible neck clamping technology to accommodate various bottle sizes. Adjustments require only guide plates and positioning wheel replacement, eliminating height reconfiguration.

- Anti-Breakage Design: Equipped with buffer mechanisms on conveyor tracks to prevent glass bottle collisions and ensure high product integrity.

- Hygienic Material Construction: All product-contact parts are made of SUS 316L stainless steel, free of dead corners, complying with food-grade standards.

- High-Precision Filling Valve: Isobaric filling technology with flow control ensures minimal liquid level fluctuation (±1ml accuracy).

- Smart Control System: Touchscreen HMI for real-time monitoring and parameter adjustments.

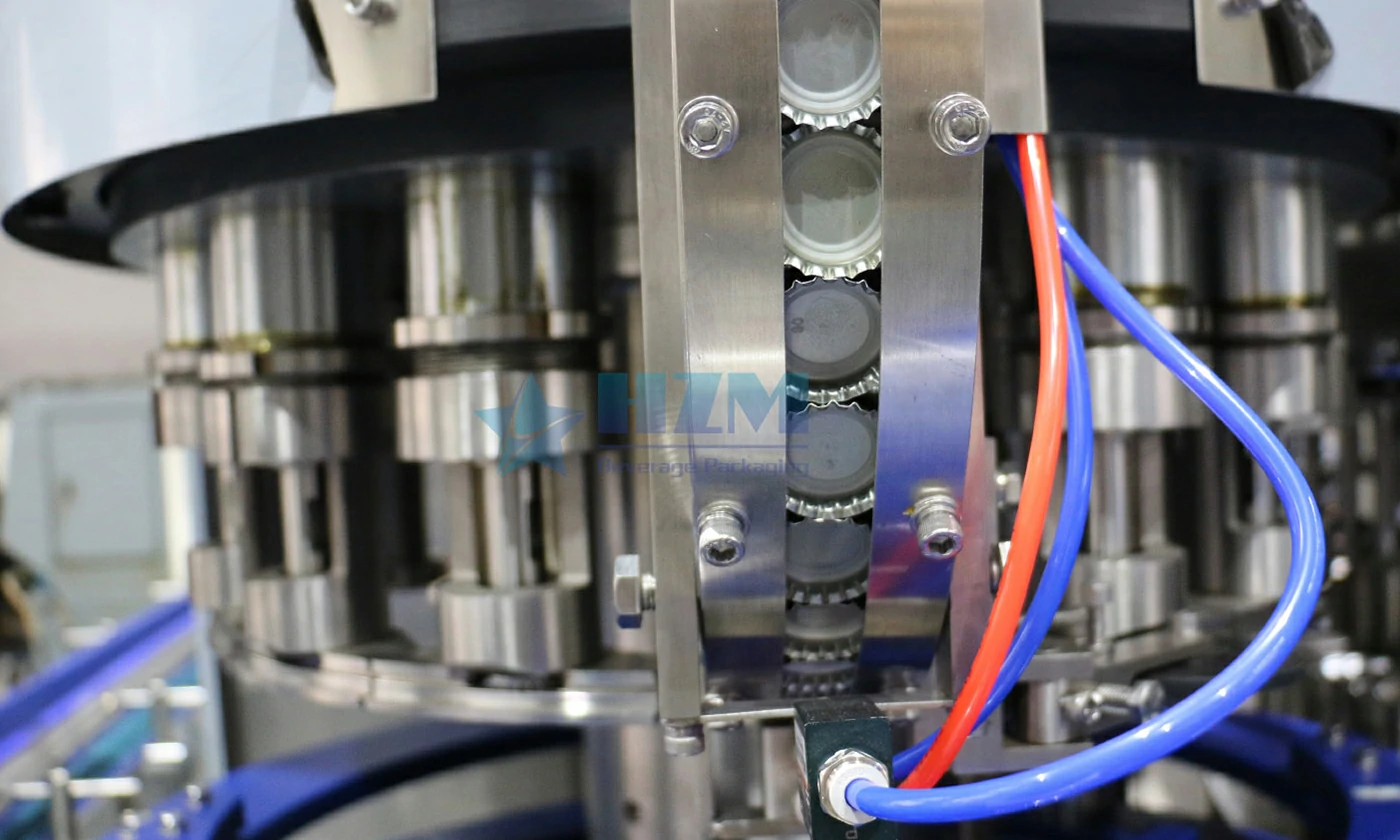

- Magnetic Torque Capping: Capping heads feature constant magnetic torque to guarantee seal integrity without cap damage.

- Comprehensive Safety: Includes cap deficiency detection, overload protection, and emergency stop functions.

- CIP Cleaning System: Automated in-place cleaning ensures sanitation and operational efficiency.